LEWA Attendorn Blog

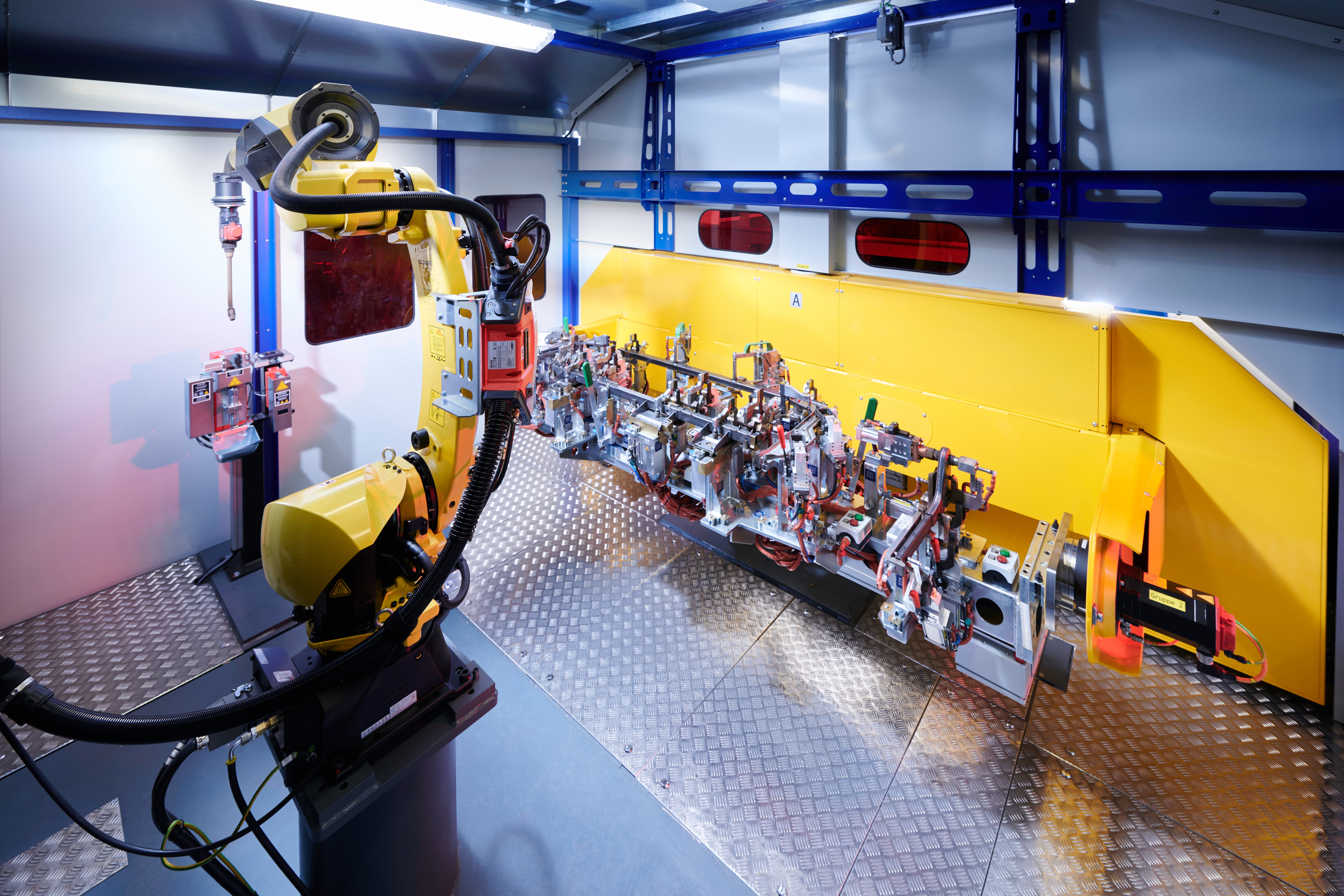

Automated joining systems: production system for MIG welding of a seat assembly

- Blog

- Automated joining systems: production system for MIG welding of a seat assembly

We explain how LEWA Attendorn develops a flexible production concept, which ensures future expansion and integration of other products in the event of volume fluctuations or design modifications according to the ReUse principle.

Customer requirement:

Design of a production system for MIG welding of a complex, heavy duty vehicle seat assembly consisting of backrest (60% and 40%) and seat bench. The goal is 30,000 units per year in a maximum of 616 seconds per seat assembly. The production system is to be manned by one operator. We developed a flexible production concept, which ensures future expansion and integration of other products in the event of volume fluctuations or design modifications according to the ReUse principle.

Application processes:

The total weld length of 8223mm is distributed over three assemblies

Seat structure = 2970mm with 97 welds

LH 60 backrest = 3189 mm with 92 welds

RH 40 backrest = 2064 mm with 49 welds

-

-

Due to large differences in material thickness, more complex welding tasks are required, including -thin sheet welding, through-welds and circumferential welds

-

High demands on geometry due to low manufacturing tolerance

-

Unsere Lösung:

Fronius PMC/CMT welding at high speed:

-

Two LEWA SpeedCells ARC 2.0

-

LEWA SpeedFrame with 2,500 mm center width for welding tools weighing up to 750 kg per turntable side. Turning time (180°) < 3.0 sec

-

High-precision tooling technology with available adjustment based on in vehicle RPS of +/- 5mm to react to welding distortion and geometry settings

-

Particular focus on the design of the assemblies and subassemblies within the tooling to ensure accessibility of the welding torches, accessibility for the operator, and for maintenance.

-

The ability to run each nest individually to support spare part requirements

-

Standard design for a flexible production concept Expandable program structures as well as the LEWA quick-change tooling mount, allow short set-up times for variants and create flexibility in production planning

-

Modular LEWA SpeedCell design - Enables expansion and adaptation for future products

The customer benefit:

Solution from one source:Concept development, equipment and tooling engineering, manufacturing, assembly, programming, commissioning , quality manufacturing – in less then 25 weeks.

-

We achieved and surpassed the required machine cycle time of 616 sec by 12% per seat assembly with simultaneous operation by one worker.

-

Start-up support for series production

You would like to learn more about LEWA Attendorn? - Sure!

Arrange an introductory meeting or web call with our team to review our capabilites and discuss your automation needs.