LEWA Attendorn Blog

Automated joining systems: a fully automated “Lights out” joining system for automotive patch plates with LEWA-SpeedLine components.

- Blog

- Automated joining systems: a fully automated “Lights out” joining system for automotive patch plates with LEWA-SpeedLine components.

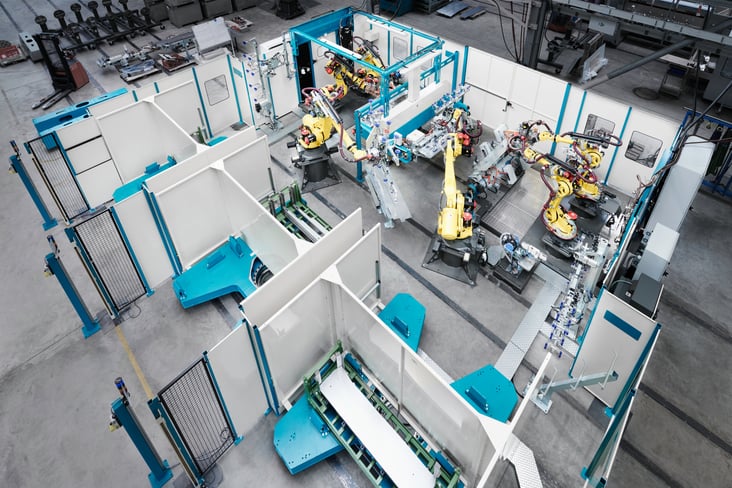

Example of a fully automated “Lights out” joining system for automotive patch plates with LEWA-SpeedLine components: SpeedGun, SpeedCell as well as camera technology

Customer requirement:

For our automotive customers we develop highly automated and "workerless" joining systems for the welding of patch plates for the production of door sills, B-pillars, A-pillars, etc.

Our solution:

The individual parts to be joined are automatically fed to the joining system via special loading turntables. The racks for individual and finished parts are changed by the plant logistics department.

The blanks are joined by spot welding - this is where our LEWA-SpeedLine comes into play.

Our spot welding gun,. The LEWA-SpeedGun, ensures reliability and performance with lower energy consumption for joining the patch blanks.

The system concept as well as its tooling technology is based on the modular LEWA-SpeedCell concept and offers the possibility to produce right and left sill plates on one system. Flexible gripper changing systems are used for this purpose, among other things.

We provide a consistent and trouble-free production process with the LEWA vision system developed and designed in-house.

Any deviations in the position of the patch plates can be independently compensated for by the flexible camera system.

Click here for the full version of the film:

If you would like to know how to run an automated production with top speed and high efficiency, please feel free to contact us.

Arrange an introductory meeting or web call with our team to review our capabilites and discuss your automation needs.