LEWA Attendorn Blog

What does "3D Bin Picking" mean?

- Blog

- What does "3D Bin Picking" mean?

Bin picking has been one of the trends in machine vision over the last 10 years. But the enormous benefits are becoming more apparent due to increasingly powerful systems on the market that are quicker, easier to use, and less prone to failure. A wisely used 3D bin picking system can make your production more consistent, faster, more efficient, in short: quite a bit more profitable. We take a look at how bin picking systems work.

Bin picking involves the automated removal of components from a bin by a robot, assisted by an optical vision system, usually statically mounted above the bin. In this way, the component can be transferred to the subsequent process in a defined position. In the best case, the bin is 100% emptied and intervention by personnel is limited to replacing the bin.

The challenge often lies in the detection of chaotically arranged components.

The challenge often lies in the detection of chaotically arranged components.

Overlapping, obscuring of clear geometric features and few options to grab the components are only a few of the problems. For this reason, bin picking in many medium-sized manufacturing companies is still done by hand by an employee or other measures are chosen to separate components beforehand in order to simplify the process. However, the latter alternative also incurs costs and requires space.

Let's now turn to the operation and the main aspects that play an important role in the design of such a system.

Project planning and sequence of a 3D bin picking system

As a rule, the container and the component to be gripped dictate how the other components are selected. This concerns:

- Vision system

- Robot

- gripper

The size of the area to be searched for suitable components and the resolution or the accuracy in which the components have to be detected determine which variant of the available vision systems is used. In principle, bin picking systems can be mounted statically above the container, but depending on the variant or size, they can also be mounted directly on the robot.

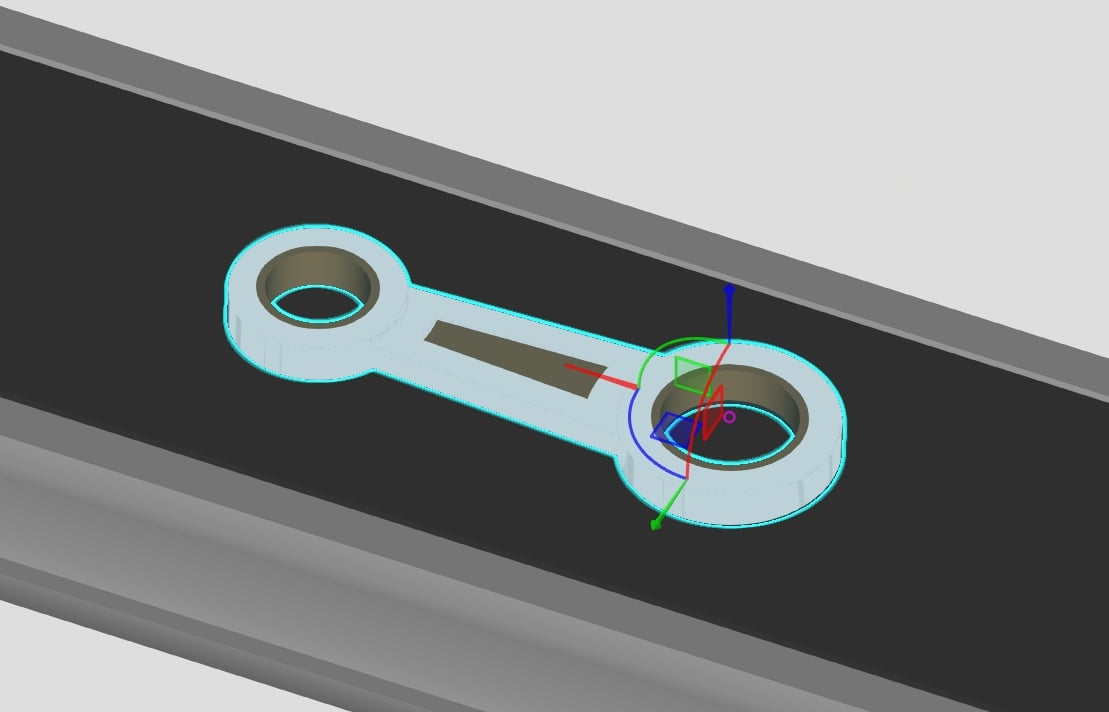

In order to avoid collisions between gripper and container as far as possible, the assembled gripper can be imported via a CAD model and in this way its extended outer contours can be communicated to the robot.

In order to avoid collisions between gripper and container as far as possible, the assembled gripper can be imported via a CAD model and in this way its extended outer contours can be communicated to the robot.

Combined with the dimension information where the the exact gripping point is located (TCP) and together with the generated 3D point cloud, the robot knows exactly which movement would lead to a collision and avoids it.

In order for the robot to know where the components it is looking for are located in the container, the robot first needs information about what the component looks like. This is most easily done if an existing CAD model can be loaded. If this is not available, one can use the existing technology and create their own 3D model using the bin picking system.

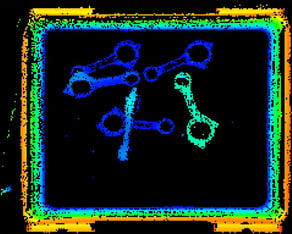

A 3D point cloud of the box with the components currently inside can be created in several ways. Often, a set of several cameras and a lighting system is used for this purpose, where the different positioning of the cameras and the simultaneous evaluation of a projected light-strip pattern enables the recording of a three-dimensional space.

After the scanning process, similarities in the generated point cloud are searched for with the model of the taught component and, in the best case, several components are prioritized for the gripping process according to certain criteria. Prioritization can be based on location, orientation, occlusion, accessibility, etc. After a component has been successfully gripped from the crate, a new scanning process can be performed in parallel with the depositing process in order to already determine the position of the next component.

Optionally, further image processing components can be used after the gripping process, such as a subsequent position check of the gripped components or an optional buffer, in order to be able to continue working in a cycle-time-neutral manner in the event of possible faulty gripping.

What are the advantages and disadvantages of 3D bin picking systems?

The advantages of automated bin picking are obvious:

- The system operates on demand, uninterrupted and with high efficiency

- It can be flexibly retooled and adapted to a wide variety of components and robot-gripper combinations

- After the investment for the setup, only minor if any, additional investments are necessary

However, the process is not suitable for all applications. The following situations can occur:

- Component characteristics may limit the reliability of the system or make the system unfeasible to implement in the first place.

- There is not enough space for a 3D bin picking system with robot

- In order to achieve a defined cycle time, a buffer section may be necessary due to poorly grippable components

Conclusion

The increasingly powerful matching algorithms to reliably extract known 3D models in a 3D point cloud, combined with the ability to dynamically evaluate and individually grab parts based on their environment, characterize today's bin picking systems. As a result, the system has already become a standard in many plants - and it certainly hasn't reached the peak of its popularity yet. For good reason: the technology is extremely efficient and can work extraordinarily economically and flexibly, provided that the necessary requirements can be met.

As a specialist in automation, LEWA Attendorn offers turnkey bin-picking systems for a wide variety of application scenarios. At the beginning of every automation project, we consult with you to determine the need, feasibility, and optimal solution for your project.

Please feel free to contact us for an evaluation of your process.