LEWA Attendorn Blog

Failure-free production - how can I make my plant fail-safe?

- Blog

- Failure-free production - how can I make my plant fail-safe?

Production downtime is probably one of the biggest fears facing ma around the globe. The costs incurred by a disruption in production can be immense - but intelligent risk assessment and systematic planning can minimize the risks of a production outage.

A production outage can have devastating economic consequences: There's the missed revenue from the actual downtime, but there's also the repair costs and cost of spare parts. For disassembly, freight and assembly, there are often also night or weekend surcharges, because of course the disruption in production always feels to pick the worst time.

Added to this are economic losses due to a delay in downstream production and possibly even damage to downstream machines - all in all, a worst-case scenario that every company would like to avoid at all costs.

Fail-safe production – is that even possible?

One hundred percent fail-safety can never really be guaranteed for sufficiently complex systems, despite technological progress and thorough considerations.

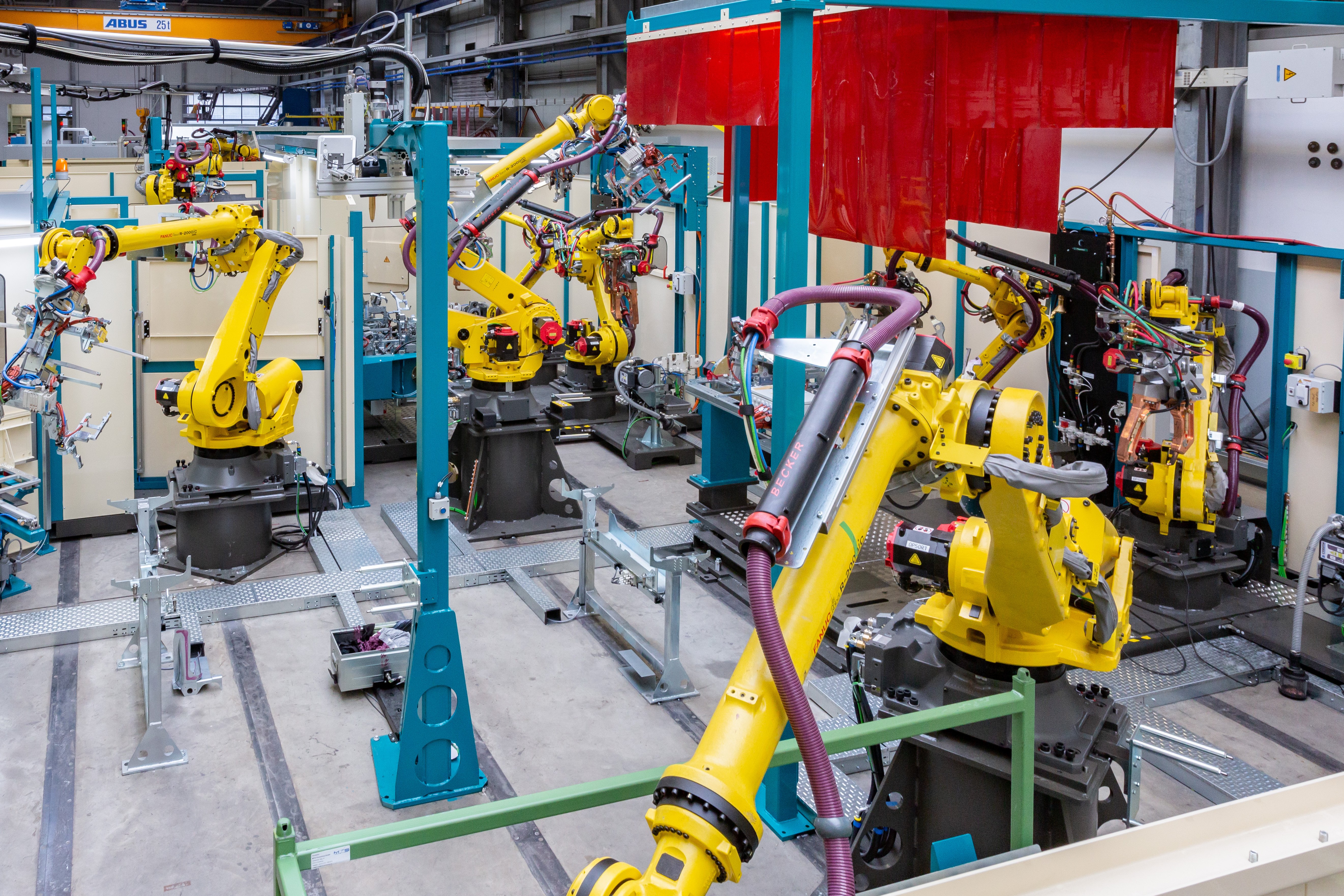

The resilience of production facilities, e.g. welding and joining systems, but also of electronic systems or supply chains, can be significantly increased with the appropriate combination of strategy and technology.

The resilience of production facilities, e.g. welding and joining systems, but also of electronic systems or supply chains, can be significantly increased with the appropriate combination of strategy and technology.

There are too many factors at play, too many dependencies to overcome. Much more important for most companies than the question "How do I achieve completely fail-safe production?" would be the question of what level of fail-safe makes sense at all - especially in economic terms.

However, with the right measures and a willingness to invest, production downtime can greatly reduced if not eliminated all together.

Measures for the most trouble-free production possible

Production downtime can generally be avoided through two approaches: Strategies and solutions for getting a value chain back online quickly in the event of a disruption - and so-called predictive maintenance, which is predictive, proactive maintenance designed to prevent downtime from occurring in the first place.

The most important measures for setting up fault-free production are as follows:

Redundant setup of key modules

Key plant sections and modules can be set up redundantly so that, if the worst comes to the worst, a machine or module can be replaced quickly and easily. At the same time, this also makes it possible to avoid having to 'rush' any repairs to the defective module and instead to guarantee that a fault has been rectified before a previously defective module resumes its work.

The advantages of a redundant setup are obvious, but the disadvantages of such a configuration are also quickly apparent:

- Increased investment requirements for production hall equipment

- Tied-up capital that cannot be used anywhere else

- Little or no utilization on the replacement assembly

Repairs without shutdown

Here comes a task for maintenance engineers and maintenance personnel: How can you design assemblies or entire plants in such a way that maintenance and repair is also possible during operation?

When a malfunction occurs in a plant, every second counts - so the personnel responsible for maintenance and repair should specialize in effectiveness and efficiency. If possible, the reasons for any faults or malfunctions should be selectively narrowed down, discovered, and quickly eliminated. Accordingly, it is advisable to have maintenance staff and fitters carry out possible repair work on a trial basis during installation and even before a plant is commissioned.

Young or new colleagues should be instructed in the details of how a plant works, possible faults should be explained, and their elimination rehearsed if possible.

Young or new colleagues should be instructed in the details of how a plant works, possible faults should be explained, and their elimination rehearsed if possible.

Checklists for troubleshooting have proven to be advisable for isolating and eliminating faults. In some cases, a complete production stoppage in the company can be averted in this way.

Predictive maintenance - predictive maintenance against production downtime

In the context of Industry 4.0 and machine learning, there is increasing talk of predictive maintenance. This refers to maintenance processes that are based on process and machine data collected and stored by an artificial intelligence (AI).

The AI constantly collects machine and operating data for this purpose. Via machine learning, the technology learns to recognize certain fault indicators, whereupon the artificial intelligence automatically calls in the appropriate maintenance strategy. The machine does this by analyzing real-time data on the one hand and an existing database on the other.

If predictive maintenance solutions are used correctly and fed with appropriate data, they are quite quickly ready to notify a technician or maintenance engineer about the necessary remediation of a problem before the problem has even occurred.

Conclusion

Truly 100 percent fail-safe production will be at least a pipe dream for a long time to come, and perhaps forever unattainable. The unpredictable human factor alone and the inevitability of human error are key contributors.

However, managers and employees can take measures to make production as fail-safe as possible - if you approach this correctly, you will come pretty close to 100% fail-safe production. It is important to distinguish between reacting and acting. Instead of being able to react as quickly as possible to a production failure, decision-makers should focus on preventing such failures from occurring as far as possible. Artificial intelligence and its implementation as predictive maintenance within Industry 4.0 make such a thing possible.

If this topic has aroused your curiosity and you would like to learn how you can also make your production more fail-safe with the right level of automation, please feel free to contact us at any time.