LEWA Attendorn Blog

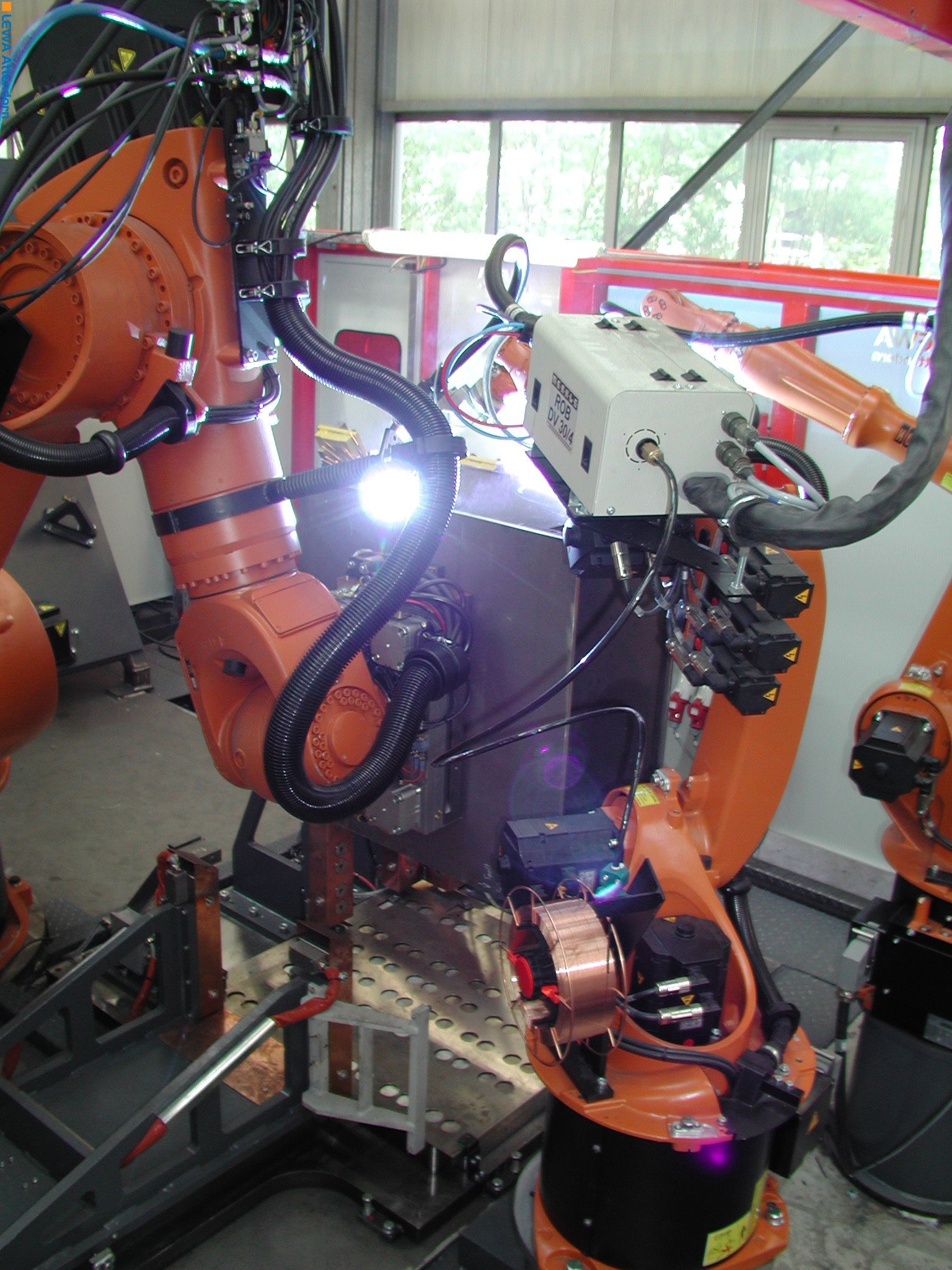

Automated joining systems: production system for the manufacture of thick-walled safety cabinets

- Blog

- Automated joining systems: production system for the manufacture of thick-walled safety cabinets

We explain how LEWA Attendorn provides its customer with a production system for the manufacture of thick-walled safety cabinets for the subsequent installation of drive and control components.

Customer requirement:

Manufacture of thick-walled safety cabinets in a wide variety and with the highest requirements for welded joints and geometric dimensions for the subsequent installation of drive and control components.

Application processes:

- Mechanical processing (milling/drilling/tapping) of the individual side elements

- MIG welding (total length up to 12,480 mm)

- Grinding - paintable overgrinding of welds

Our solution:

Construction of a highly automated production line.

- Design and construction of a CNC-controlled clamping device for max. flexibility of the products

- Flexible fixture and gripping technology including an automated set up process for component variations.

- Fully automated manufacturing process: from picking up the individual parts to tacking and welding out the components with subsequent overgrinding of the weld seams and transfer to the paint line.

The customer benefit:

Maximum flexibility to a wide range of dimensions and component types.

- Highly automated solution for consistently high quality and productivity

- Several manual operations and transport efforts were replaced via an automation solution

You would like to learn more about LEWA Attendorn? - Sure!

Arrange an initial appointment without obligation and get in touch with us.