LEWA Attendorn Blog

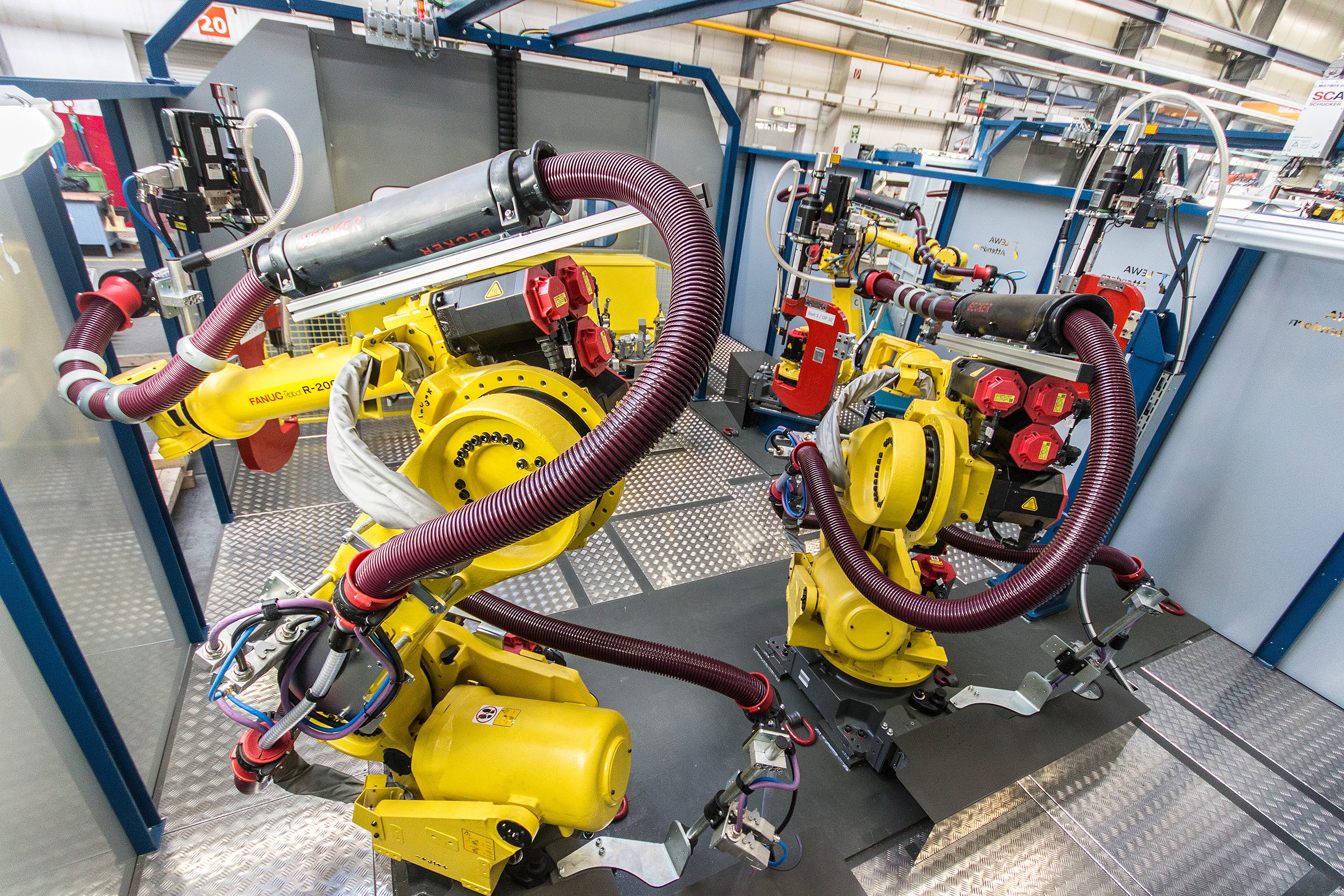

Automated joining systems: production system for two rear floor variants

- Blog

- Automated joining systems: production system for two rear floor variants

We explain how LEWA Attendorn designed a production system for its customer to manufacture two steel and aluminum rear floor variants.

Customer requirement:

Conceptual design of a production system for the manufacture of two steel/aluminum rear floor variants with planned, staged, volume increases

Application processes:

- Punch rivets (68 pieces/assembly)

- Gluing incl. vision control (number of seams, total length)

- Material handling with customer EOA tooling and dedicated part racks

Our solution:

Construction of a highly automated production line from standardized SpeedLine modules

- Limited operators resulting in greater machine efficiency and through put

- Variable fixture and gripper technology including automated setup process

- Joining by means of servo-driven self-pierce riveting technology

- Automated adhesive application with process monitoring utilizing vision

- Parts marking and documentation of production data

- Stacking of the assemblies in the dedicated racks

The customer benefit:

SpeedLine standard production modules are characterized by the following advantages:

- Cost-optimized modules that have been successfully used in over 100 production solutions

- Maximum flexibility and can be set up for other products via the tooling technology used

- Scalable to the required capacities (product start-up, peak, product run-out)

- Designed to be relocated very quickly within the company or across the group

- Designed for longevity, flexibility and reutilization for future programs.

You would like to learn more about LEWA Attendorn? - Sure!

Arrange an initial appointment without obligation and get in touch with us.