LEWA Attendorn Blog

The best of both worlds: Automated laser hybrid welding and its benefits

- Blog

- The best of both worlds: Automated laser hybrid welding and its benefits

The advent of laser hybrid welding was certainly one of the most disruptive developments in the field of welding technology in the past 15 years. In the intervening years, the process has been able to prove its suitability in the industrial sector beyond any doubt. We explain how laser hybrid welding brings together the best of both worlds and what requirements your production process should meet to ensure the right return on investment.

Laser hybrid welding is a combination of laser welding and arc welding (gas metal arc welding or MIG/MAG welding). The hybrid process can increase welding speeds, improve joint quality and reduce costs. Laser hybrid welding can be far more profitable compared to using the individual processes.

How does laser hybrid welding work?

As the name suggests, laser hybrid welding is a hybrid process - consisting of the elements of laser penetration mode or keyhole welding and gas metal arc welding.

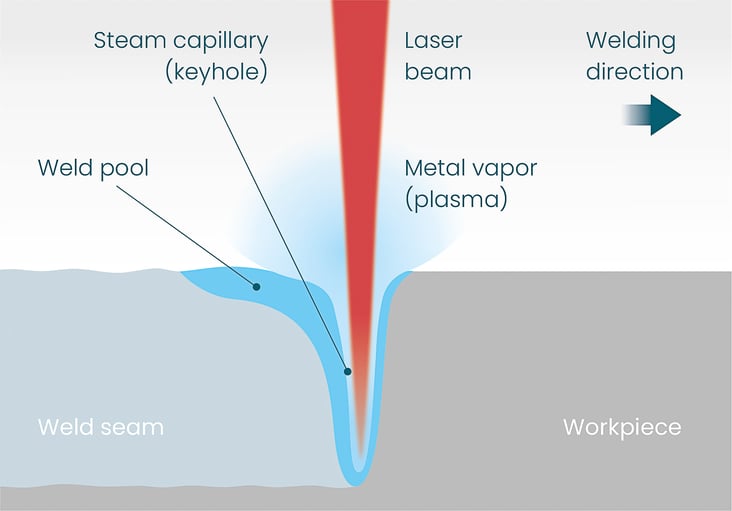

Laser keyhole or penetration mode welding

Lase welding utilizes a very concentrated heat source allowing for a very narrow and very deep (keyhole) penetration of the material. A focused laser beam with very high energy intensity is used to heat the metal to be welded to such an extent that molten metal and metal vapor are generated. Laser welding brings with it the following process characteristics.

The precise and only briefly applied energy leads to low material distortion and enables very high welding speeds. The seam depths are very high in laser welding. However, the ability to bridge gaps in the joint is low due to the concentrated laser beam. This means that the requirements for workpiece preparation are very high.

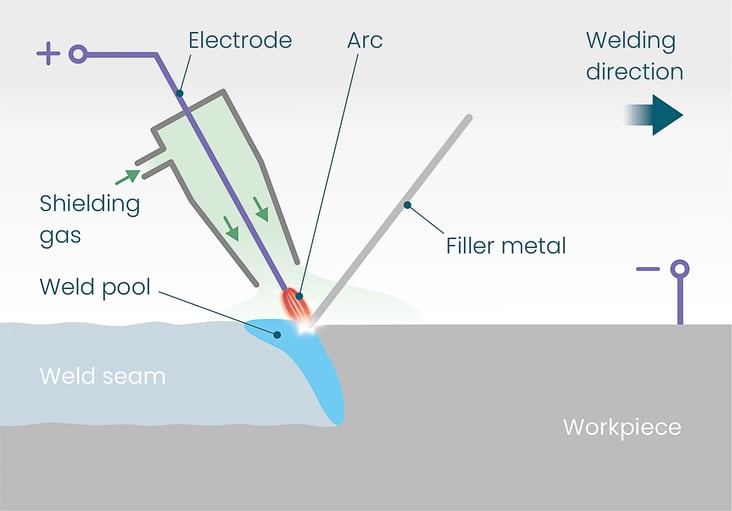

Arc welding (MSG/MIG/MAG welding)

In gas shielded arc welding, the metal is heated not by a laser but by an arc between the wire electrode and the base metal. In this process, the weld seam is covered by shielding gas, which flows out around the electrode. This gas protects the resulting molten metal from the surrounding air and prevents porosity.

Arc welding (MIG welding) offers a better solution for filling gaps than laser welding because filler metal is added in the process. However, arc welding is also slower than laser welding, creates a shallower penetration profile, and causes greater material distortion.

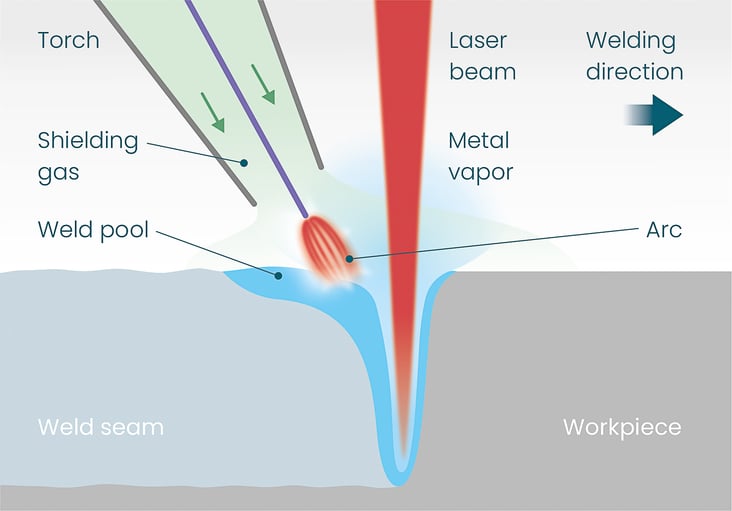

Laser hybrid welding

Laser hybrid welding combines a laser welding system and an arc welding system.

Both processes work simultaneously in the same molten pool.

With the focused laser beam, a deep penetration is achieved. With the arc welding process, filler metal is added and the weld pool is widened.

This results in synergies: The advantages of laser welding, high penetration depth, fast welding speeds and low material distortion are retained. Simultaneous arc welding significantly improves gap coverage. Heat input is low due to the narrow penetration and higher speeds resulting in only minor component distortion. The result is an easily controllable hybrid welding process with very high welding speeds and deposition rates.

Where is laser hybrid welding used?

Thanks to the high penetration depth, laser hybrid welding is used primarily - but not exclusively - for thicker materials and when longer weld seams are required, for example in heavy industry and in rail vehicle and ship construction. Because laser hybrid welding can achieve penetration depths of over one centimeter and welding speeds of up to 7 meters per minute, it is the perfect solution here.

However, the process is also well suited for thinner material starting at 3 mm: The gap coverage, high speed and reduced heat input make laser hybrid welding a good choice here as well.

Is laser hybrid welding also suitable for my production?

Due to the high welding speeds, automated laser hybrid welding systems are particularly economical when assemblies with long weld seam lengths or in large quantities are to be joined.

The low distortion welding and clean seam optics can reduce or eliminate rework and weld quality

Assemblies designed for an automatic laser process usually also meet the requirements for automatic laser hybrid welding.

Two important considerations for your production process for laser hybrid welding to be successful:

- Reduce gaps as much as possible

Yes, laser hybrid welding compensates for the otherwise low gap tolerance of laser deep penetration welding with MIG welding - but only within certain limits. Slower welding and the creation of thicker welds could weld larger gaps, but in doing so they would undermine one of the key advantages of laser hybrid welding - its high speed.

- Relatively simple part geometry

Laser hybrid welding is most suitable for welding parts with contours that are as straight or only slightly curved as possible - after all, this is where the speed advantage is most likely to come into play. More complex part geometries could also be processed with laser hybrid welding, but the speed advantages are diminished.

Conclusion

LEWA's joining systems are known worldwide for their high performance and speed. It goes without saying that our joining systems are also capable of laser hybrid welding. If this joining process and its advantages have aroused your curiosity, our engineering experts will be happy to advise you on all questions relating to this technology, which could perhaps also be the right solution for your production.